4 Water Meter Types and Common Water Measurement Devices

Modern water measurement technology continues evolving in 2025, with conventional devices like positive displacement and velocity flow meters remaining the workhorses of the industry, while advanced non-mechanical designs (electromagnetic and ultrasonic meters) gain broader adoption across commercial and industrial applications.

Advanced Metering Infrastructure (AMI) Integration

Water utilities are increasingly seeking remote monitoring capabilities to enhance efficiency and improve customer service. Select water meter models now integrate with Advanced Metering Infrastructure (AMI) systems, enabling automated readings and real-time data collection, eliminating the need for traditional manual meter reading routes.

What is the difference between a water meter and a water flow meter?

A water meter measures the quantity or volume of water that passes through a pipe or meter. The standard measurements are in gallons or cubic feet. The water meter may also provide totalized flow (the cumulative volume of water passing through the meter).

A water flow meter measures the speed or flow rate of water passing through but also may provide different characteristics of the liquid, such as:

- Flow rate

- Quantity

- pH

- Quality

- Electric conductivity

A water flow meter may also calculate water bills or indicate the quantity of liquid needed to add to a process.

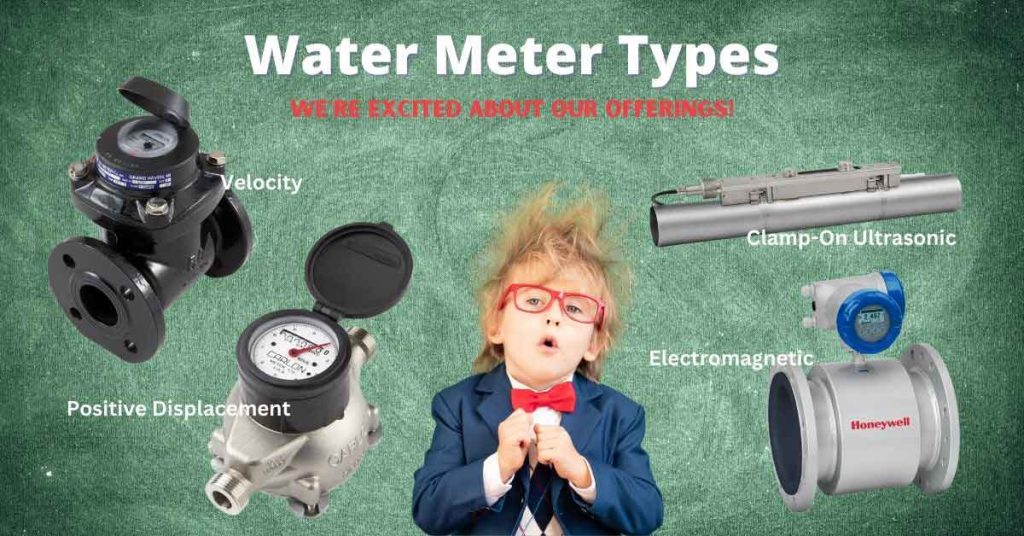

What are the four most common water meter types?

The most common types of water meters are mechanical (positive displacement and velocity meters), while non-mechanical designs (electromagnetic and ultrasonic meters) are less common.

#1 Positive Displacement Meters

The Carlon JSJ water meter is a positive displacement meter.

The positive displacement meter (PD meter) is a standard residential and small commercial water meter. It is the most common type and generally very accurate at the low-to-medium flow rates typical in these applications, typically ranging from 5/8″ to 2″. Water usually displaces a moving measuring element in this meter type, which is directly proportional to the volume of water passing through the meter. The movement directs a magnet that drives the register.

These meters have moving parts, which means that some maintenance and repair costs will be associated with their upkeep.

Select Carlon positive displacement models can integrate with AMI systems for automated reading while maintaining the measurement accuracy these meters are known for in residential applications.

#2 Velocity Flow Meter

Carlon SSMR with digital remote counter is a multi-jet meter.

A velocity meter measures the water flow velocity through the device, taking into account its internal capacity. The flow speed is converted to a volume of flow to determine consumption. There are three different types of velocity meters:

Single and Multi-jet Meters

This style of water meter has a blade rotated by water jets at a known speed. An internal strainer prevents the jets from clogging. This type of meter is effective at low water flow and small diameters. It is used primarily in domestic secondary billing, water monitoring, batch control, and small industrial applications.

The single-jet style is a low-cost, simple, and suitable option for submetering applications. A single port creates a jet stream of water with a single direct impact, rotating the turbine and transmitting the motion to a display mechanism that measures the passing volume.

Similarly, the multi-jet meters have multiple ports, each creating a jet of water that hits an impeller surrounding an internal chamber. Multi-jet meters retain accuracy at lower flow rates. They are ideal for large water users and industrial water installations. They record real-time data and, therefore, can convey changes in water consumption.

Turbine Flow Meters

The turbine-style meter is suitable for low-flow conditions with high volumes in large-diameter pipes, such as those found in industrial or commercial settings. The meter has blades on an internal rotor angled to rotate with the water flowing through it. Magnets are used to measure the speed of the blades’ rotation, and regardless of the turbine’s direction of rotation, clockwise or counterclockwise, the meters are accurate.

Compound Water Meters

Compound water meters combine positive displacement and turbine technologies to deliver accurate measurements in applications that experience rapid and wide fluctuations in water demand. The meters are suitable for hospitals, universities, large residential complexes, manufacturing facilities, and processing plants.

Current multi-jet meters feature enhanced materials and coatings that extend service life in challenging water conditions, with some models offering lifespans of 20 years or more in typical residential applications.

#3 Electromagnetic (Mag Meters)

The magnetic (mag meter) or electromagnetic water meter is ideal for water and wastewater applications, offering long-term reliability and stability. Magmeters have no moving parts, require minimal maintenance, have low repair costs, and measure volumetric flow with high accuracy.

The magnetic (mag meter) or electromagnetic water meter is ideal for water and wastewater applications, offering long-term reliability and stability. Magmeters have no moving parts, require minimal maintenance, have low repair costs, and measure volumetric flow with high accuracy.

Electromagnetic flow meters consist of a transmitter and a sensor that work together to measure flow. The sensor is placed inline and measures an induced voltage generated by the fluid as it flows through a pipe. The transmitter converts the voltage generated by the sensor into a flow measurement and transmits it to a control system.

The Honeywell VersaFlow Mag 1000 is designed for use in water and wastewater applications. The model’s long-term reliability and durability make it the industry standard for water flow sensors.

The Honeywell VersaFlow Mag meters integrate seamlessly with AMI systems, combining accurate flow measurement with remote monitoring capabilities. These meters offer enhanced diagnostics and predictive maintenance features for municipal and industrial applications

#4 Ultrasonic Water Meters

Ultrasonic water meters use ultrasound to measure the speed of the fluid. There are two distinct ultrasonic meters: transit time and Doppler.

Transit-Style Ultrasonic Meter

Transit-style ultrasonic meters are accurate in low-flow conditions, have no moving parts, and have a long lifespan. They provide real-time data. They are preferred when installing in retrofit situations where space is limited, as the meter can be installed in various positions. The downside of this meter type is that it is more expensive upfront than some alternatives.

The Honeywell VersaFlow Ultrasonic is a clamp-on-style meter installed on the outside of a process pipe. It uses transit-time technology and is ideal for clean liquid applications. It reduces installation downtime and provides significant cost-effectiveness compared to inline flow measurement equipment, especially in larger pipe sizes.

The Honeywell VersaFlow Ultrasonic is a clamp-on-style meter installed on the outside of a process pipe. It uses transit-time technology and is ideal for clean liquid applications. It reduces installation downtime and provides significant cost-effectiveness compared to inline flow measurement equipment, especially in larger pipe sizes.

Doppler-Style Ultrasonic Meter

Doppler-style ultrasonic flow meters use wrap-around sensors installed outside the pipe. They are simple, inexpensive, and used in the mining industry, sewage, or applications where solids are present. The Doppler-ultrasonic meter is not as accurate for clean liquids.

Honeywell VersaFlow Ultrasonic meters support AMI integration for remote monitoring applications. Their non-invasive clamp-on installation, combined with automated reading capabilities, makes them particularly attractive for retrofit projects that require minimal system disruption.

Frequently Asked Questions About Water Meter Types

Which water meter type is most accurate for residential use?

Positive displacement meters typically offer the highest accuracy for typical residential flow rates, particularly at the lower flows commonly found in homes.

Can water meters be retrofitted with AMI capabilities?

Select models from our Carlon line and Honeywell VersaFlow electromagnetic and ultrasonic meters support AMI integration. This allows utilities to implement automated reading systems without complete meter replacement in many cases.

How long do different water meter types last?

Positive displacement meters: 15-20 years; Velocity meters: 10-15 years; Electromagnetic meters: 20+ years; Ultrasonic meters: 15-25 years, depending on application and maintenance.

What’s the difference between a water meter and a flow meter?

Water meters measure total consumption (volume), while flow meters measure the rate of flow and can provide additional data, such as pressure, temperature, and real-time usage patterns.

Need Expert Guidance on Water Measurement Solutions?

Whether upgrading existing infrastructure or planning new installations, selecting the right water measurement technology requires understanding your specific application requirements. Our team specializes in both traditional and smart water metering solutions.

Contact us today for:

- Water meter sizing and selection assistance

- Smart metering integration planning

- Retrofit and upgrade consultations

- Technical support for existing installations

Call (303) 697-6701

-

[…] of water charge that is assessed by water utilities. They are typically based on the size of the water meter and the amount of water that is used. Tap charges can also be based on the type of water service, […]

Leave a Comment

Nice Blog!! The content you have shared is very elaborative and informative. Thanks a lot for sharing such a great piece of knowledge with us.

The water consumption trends and reports help you better understand your consumption and bring changes for better utilization of water.mablei water meters measure water using ultrasonic sensors, so there is no wear and tear as in mechanical meters. The smart electronic circuits take the meter readings and upload the data without manual intervention

Comprehensive blog I learnt a lot as I contemplate to setup a water meter assembly plant in Uganda

Interesting there is no mention of Ultrasonic meters?? All your PD meters are referred to as highly accurate…..Are you saying Ultrasonic is NOT more accurate than PD or Nutating Disc??

Yes, ultrasonics are mentioned above. They are less common. They are more expensive and accurate in clean water.