How to Change an Itron B34 Regulator Orifice?

In the following article, we answer, “How do I change my Itron B34 regulator orifice? Of course, these instructions apply to all Itron B34: R, N, M, and D natural gas regulators. In addition to the Itron guidelines, it is important to adhere to your company’s procedures.

B34 Natural Gas Regulator

The Itron B34 Regulator is ideal for many commercial and industrial burners, gas engines, boilers, and furnaces. The B34’s fast response makes it well-suited for mid-range applications where quick on/offloads cause shock difficulties. The unit is reasonably priced and provides versatility to meet challenging applications. Itron gas regulators offer the highest level of safety with available internal monitor and relief options to control gas flow.

How to Change an Itron B34 Orifice?

Locate and remove the two bolts holding the diaphragm case to the valve body.

Locate and remove the two bolts holding the diaphragm case to the valve body.- Carefully pull the diaphragm case away from the valve body. Inspect the valve seat, valve body and valve body gasket for any debris, damage, or deterioration. Replace the valve body gasket.

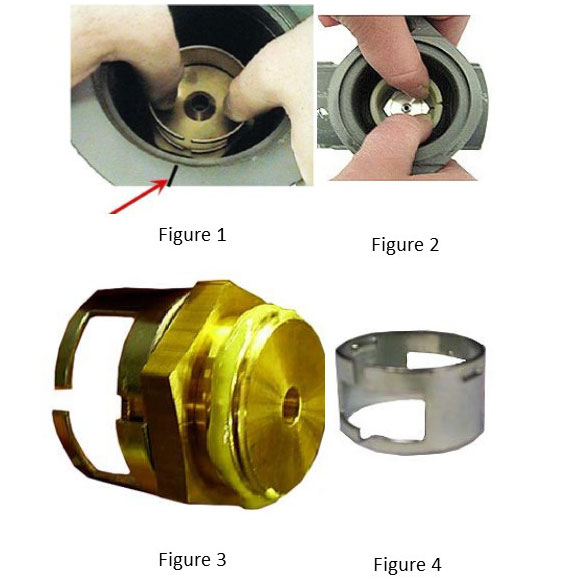

- Note the loading ring’s position. The loading ring must be replaced in the same position. Use a marker to indicate the position of the loading ring’s notch on the valve body (see Figure 1).

- Place your thumbs in the neck of the loading ring. Gently open the loading ring and remove (see Figure 2).

- Remove the orifice using a 1-7/16-inch thin-wall socket wrench.

- Apply pipe thread sealant (Rector Seal #5) on the orifice threads. (See Figure 3.) Begin threading the orifice by hand, using the ratchet to finish tightening. Torque to 600 inch-pounds. Do not over-tighten the orifice. Warning: Over tightening the orifice can cause irreparable damage. Torque to 600 inch-pounds.

- Replace the loading ring to its original position. Verify the orifice retention beads seat against the orifice.

- Reattach the diaphragm case to the valve body. Tighten the bolts in an alternating fashion; tighten each bolt one-half way. Tighten both screws completely; torque to 100-inch pounds.

- Slowly pressurize the system. Verify the regulator locks up and regulates properly.

For the recommendation of tools and parts needed and the loading ring position, download the Itron instructions.

Images and information courtesy of the Itron Gas Regulator.

Thanks a lot for posting this post, Your post has always been an informative source for me.

Air Compressor