GPL 750 Odorizer – Principle of Odorant Injection System Operation

GPL Odorizers manufactures cost-effective, planet-friendly odorization solutions using advanced technology to deliver safe, accurate, and reliable odorant injection for natural gas, biogas, and propane. The GPL 750 odorizer operation is unique, and the following highlights its working principle.

GPL 750 Odorizer Operation Overview

The GPL 750 odorizer is an uncomplicated system, has long-lasting performance, is easy to maintain and operate.

The GPL 750 uses proprietary drip technology, permitting precise odorization in even problematic ranges, such as low-volume (even no-flow) and intermittent-volume applications from 0-24 MMSCFD on pipelines with pressure ranging from 40 to 250 PSI. The odorization system is appropriate for small city gate stations, municipalities, and methane (biogas) producers.

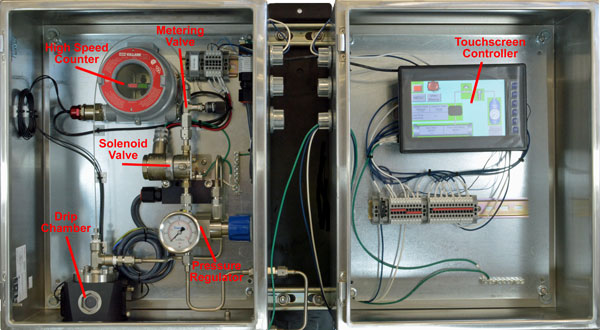

The GPL 750 is a solenoid-driven odorant injection system with a clean, sealed, and ventless design since pipeline gas does not actuate the injector. No gas or odorant ever discharges into the atmosphere from the odorizer; therefore, there is no smell during regular operation and maintenance. This design alone contributes to lowering false leak-call complaints commonly associated with the operation of an odorization system. Additionally, with only one moving part, the GPL 750 odorizer is an uncomplicated system, has long-lasting performance, is easy to maintain and operate.

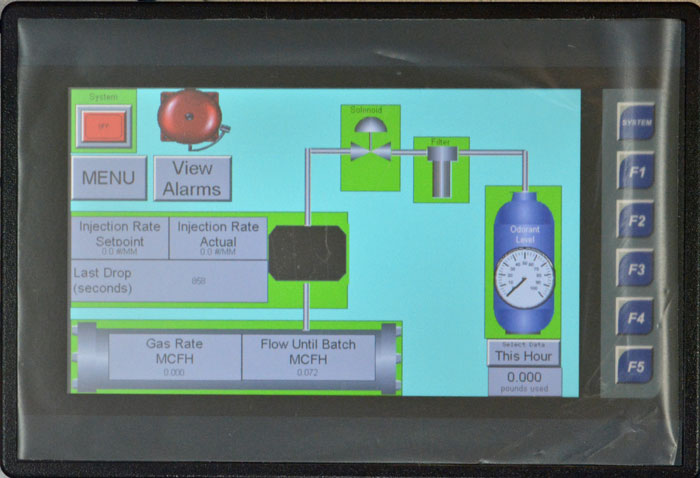

Intuitive 7″ Touchscreen PLC

PLC Interfaces with Injector

An industry-leading programmable logic controller (PLC) interfaces with the flow meter and the odorizer’s system components, automatically compensating the injection rate to provide uniform odorant distribution.

Drip Technology

The odorizer accurately doses the gas with odorant in individual droplets of 0.01 cm3. An optical sensor counts each droplet and communicates the information to the PLC. The PLC, having the gas flow rate through the flowmeter, instructs the injector to introduce the next odorant dosage when sufficient gas flows. The dose is calculated and optimized based on the flow rate and the configured injection rate. The dosage can vary, from one to multiple drops, to provide optimal and consistent odorization, which maximizes the components’ life. The optical sensor can accurately record as many as six drops/second; however, the corresponding flow rate for such a high odorant dosage is improbable. If an extra drop of odorant falls during dosing, the optical sensor recognizes it, and the PLC allows additional gas to flow before the next dose.

The target period between doses is three minutes; however, the optimization algorithm creates some variation between dosages to compensate for flow rate fluctuations.

Gas Mass Flow Meter

Since the gas flow determines the odorant injection rate, precise flow ensures accurate odorization. GPL Odorizers use the GPL 100 to determine the gas flow. The GPL 100 thermal mass flow meter has excellent low-flow sensitivity and high rangeability, and both parameters ensure accurate, optimal, and repeatable odorization, even in low-and intermittent-flow systems.

Odorant Pressure and Injection Rate

A spring- and dome-loaded regulator automatically controls the odorant’s pressure to the injector based on pipeline pressure to ensure consistent dosing.

The PLC calculates the odorant injection rate and determines the total odorant usage. The optical comparator generates a pulse when a configurable mass of odorant flows. Both the measured gas flow rate and mass of injected odorant stores hourly on the PLC SD card. The data is available for regulatory or company documentation.

Self-Monitoring and Real-Time Alarms

The system is self-monitoring. If the GPL 750 is unable to odorize within the configured settings, an external alarm is sent to specified PCs and smartphones. Alarm conditions are stored and time-stamped in non-volatile memory (SD card).

Mechanical Mode During Power Failure

In the event of a power failure, a temporary mechanical mode can provide an acceptable odorant injection by opening the solenoid and adjusting the pressure regulator. In this situation, the flow computer goes down because there is no power on-site; however, the manual fix safely odorizes gas for delivery.

If you are interested in learning more about the GPL 750 odorant injection system, download the GPL 750 datasheet, download the GPL Odorizer brochure, or request a quote now.