Sage Paramount

The Sage Paramount meter is the newest addition to the Sage Metering family and is designed for industrial applications. While the thermal mass flow meter looks much like the Sage Prime, some key differences exist.

Sage Paramount Industrial Flow Meter

Sage Paramount 400 Series is a heavy-duty industrial thermal mass flow meter for measuring air and gas mass flow. It achieves gas mass flow accuracy of +/- 0.5% of full scale +/- 1.0% of reading. The meter utilizes an advanced microprocessor, permitting Sage meters’ fastest response to temperature changes. The Sage meters use a proprietary digital hybrid circuit sensor that delivers no drift and improved performance, resolution, and reproducibility. The SageCom software is included with the purchase of the Paramount meter. The Paramount also has optional Bluetooth and three Ethernet options available to network critical flow data from the meters to the user’s control system: Ethernet/IP, Modbus/TCP, or BACnet/IP.

Sage First-to-Market Benefits:

- Sage meters offer Bluetooth wireless connectivity for remote programming.

- The Sage Digital Hybrid Circuit ensures improved performance and reproducibility.

- Sage In-Situ Calibration Verification validates sensor cleanliness and calibration without removing it from service, saving time and money.

Additional advantages of Sage Paramount:

SageCom™ Validation & Configuration software is included.

SageCom™ Validation & Configuration software is included.- Inline meters have built-in flow conditioning that reduces straight-run requirements, while Captive Flow Conditioners assist insertion-style meters.

- Sage meters meet EPA regulations for greenhouse gas reporting and quantifying carbon credit protocols

- Sage meters have the lowest power dissipation in their class, with under 100 mA at 24VDC

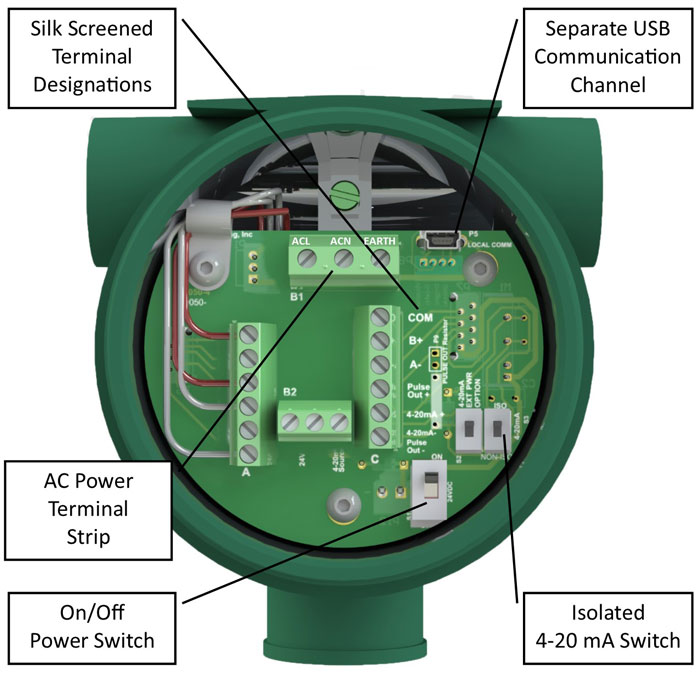

- The device provides both an isolated 4-20 mA output and a pulsed output of the totalized flow

- RS485 RTU communication protocol is compliant with Modbus® standards, with HART™ optional

- A separate USB communication channel and mini-USB allow independent connection with SageCom without disrupting MODBUS output

- Flow rate, total, and temperature displayed on high-contrast photo-emissive OLED with a graphical flow indicator

- The meter's display continuously shows the calibration milliwatts (mW), which provides ongoing diagnostic data

- The remote style allows electronics up to 1000 feet from the probe with lead-length compensation

- CL I Div 2 (with CL I Div 1 optional) is the standard hazardous area classification, and the meter enclosure is rated NEMA 4X

- A 1/2” diameter probe is standard with a double sealed sensor for insertion style. A Rugged 3/4” probe is optional

- Bluetooth communication between the meter and SageCom is optional

- Ethernet communication between the meter and SageCom (24 VDC operating power only) is optional

Natural Gas—Thermal mass flow meters are not AGA-approved for custody transfer. However, they are acceptable for measuring natural gas flow in combustion control, GHG reporting, submetering, and real-time gas measurement in pipelines.

Flare Gas—Gas flares burn off excess or unintentionally released gases. They are used in natural gas production and distribution, oil refineries, wastewater treatment, and the steel industry. In these applications, thermal mass flow meters are ideal for measuring gas flow.

Energy Management—As industries adopt energy management systems, they must establish baseline gas usage and continuously monitor it to improve the process. Within these systems, thermal mass flow meters excel in natural gas consumption, combustion control, and compressed air monitoring.

Combustion—Combustion is the process of burning fuel in the presence of oxygen, and its efficiency depends on the air-to-fuel ratio. By measuring the air and natural gas flow to a combustion device, the user can create optimum operating conditions to achieve complete combustion.

Biogas—Thermal mass flow meters measure biogas and offer advantages over alternative flow meters. This meter type satisfies gas measurements at wastewater treatment plants, waste-to-energy projects, and landfills.

Industrial Air—Air is a mixture of gases. Many industrial and commercial applications use thermal mass flow meters, including combustion air, compressed air, spray drying, and aeration air.

- Midstream Oil and Gas

- Upstream Oil and Gas

- Wastewater

- Waste

- Steel

- Pharmaceutical

- Biotech

- Textile

- Paper

- Power Generation