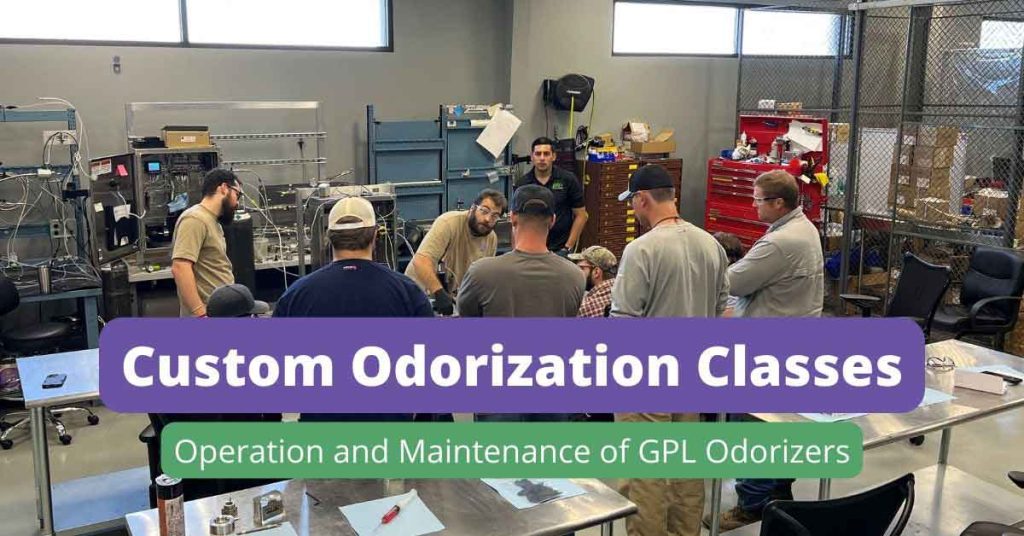

Custom Odorization Class

Linc Energy Systems is an authorized trainer for GPL Odorizers and instructs in the safe and efficient operation of GPL 750, GPL 5000, and 10000 odorization systems. We offer classes to teach users of GPL equipment to ensure the GPL Odorizers’ clients understand the proper use of the equipment and satisfy the manufacturer’s requirements, the client’s safety policies, and potential regulatory requirements.

The odorization equipment training class was very informative, insightful, and hands-on. I was able to develop a deeper understanding of the unit thanks to this course.”

—Ryan Minato, Field Engineer, Pipeline Conditioning

Custom Odorization Class

A Custom Class is instruction tailored to meet the client’s individual needs. Does the following describe your needs? (If so, the Custom Class is for you):

- We have multiple employees who need training.

- We prefer a company-only private course.

- We have looked at the standard class content (Standard 750 and Standard 10000) and want modifications to better reflect our company’s needs.

- We need instruction on multiple GPL models.

- We need training on the GPL 5000.

The Custom 750/10000 Class (Training for GPL Odorization Systems) is a comprehensive course with classroom and hands-on instruction focused on the safe operation and maintenance of a GPL 10000 and/or a GPL 750 Odorization System. Upon successfully completing the class, the student will receive certification that the employee has completed the course requirements.

The instructors will teach the annual maintenance procedures, including changing filters and replacing solenoids. They will also teach how to blow the unit down to service the pump and change seal cartridges and bellows. The class will also go over the ins and outs of the HMI controller, check pump performance, and repriming the pump. (Items covered will depend on the odorization system).

Class Dates

Class dates are determined between the client and Linc Energy Systems.

Custom Class

This Custom Class will satisfy GPL Odorizers’ recommendation that its users be trained in the equipment’s proper operation and maintenance. Failure to comply with properly operating and maintaining the equipment can void the warranty, destroy property, cause injury, or even worse.

If you’re interested in discussing a Custom Class for your company, with your contact information using the “Questions or Reservations” link above, or call (303) 697-6701.

Class Duration

Class Duration

The client’s needs will determine the length of the Custom Class.

This Custom Class is for employees, contractors, and operators of GPL 10000 or 750 odorization systems.

This Custom Class is for employees, contractors, and operators of GPL 10000 or 750 odorization systems.

The student is trained in the safe and efficient operation of the GPL Odorizers equipment and will receive certification that they have been trained in the equipment operation upon successful completion.

Content included in the class will depend upon the client’s needs. However, the following are typically covered in the Standard Classes:

- Operation of the odorizer (GPL 750 and/or 10000)

- HMI Interface

- Reprime the Pump (10000)

- Mercaptan purge (10000)

- Purge Loop (10000)

- Equipment blowdown (750)

- Maintenance

- Accessing Data and Creating Reports

This course is for men and women who operate GPL odorization equipment.

The Custom Class will give the student new skills to meet the needs of most employers’ workplaces. It ensures that the student knows how to safely operate the GPL odorizer’s critical functions related to their workplace role. The class may assist the client with maintaining regulatory compliance.*

- Maximum students per class: 8

- Student-to-teacher ratio is 8:1 (max) in the classroom setting

- Student-to-teacher ratio is 4:1 (max) during the hands-on-training

*It is the client’s responsibility to determine if their business must comply with various regulations.

- PHMSA requires that pipeline operators qualify employees and contractors working on pipeline odorizers.

- OSHA requires employers to provide a safe workplace and safety training to operate their equipment.

The course outline is subject to change based on the customized portion of the class. The student will have a balance between classroom instruction and hands-on experience allowing the student to perform maintenance tasks (e.g., replacing seal cartridges, bellows, filters, and solenoids).

-

- Odorizer overview (classroom instruction)

- Odorization overview

- Specifications of the odorizer

- Break

- System overview

- HMI interface

- Mechanical interface

- Lunch

- Annual maintenance

- Replacement and working on the odorizers

- Replacing of seal cartridges, filters, seal cartridges, bellows

- Questions?

Course materials included:

- User Manual of the odorizer

- Operations Manual of the odorizer

- Written test

At the end of each class, the student must take a test to demonstrate a sufficient understanding of the equipment’s safe, proper, and efficient operation. When passed, the student will receive a certification of successful completion, satisfying the manufacturer’s training recommendations.

This certification may also satisfy the employer’s safety training program and help keep the employer compliant with regulatory agencies requiring safety training on equipment the employee uses.