What is turndown ratio in gas measurement?

Having sold gas flow meters for decades, I’m often asked, “What is turndown ratio?” While the turndown (turn down) ratio is usually in the flow meter’s specifications, it’s rarely explained what it means.

What is the meaning of turndown ratio in flow meters?

Sage Paramount thermal mass flow meter

Turndown ratio is also commonly referred to as rangeability. It indicates the flow range a meter can accurately measure natural gas (or whatever the gas). In other words, it’s simply the high end of a measurement range compared to the low end, expressed in a ratio and calculated using a simple formula.

Turndown Ratio = maximum flow / minimum flow

To put this in perspective, if gas flow is expected to run between 350,000 cubic feet/day and 3,500,000 cubic feet/day, the application would have a turndown ratio of 10:1. Turndown is one of the critical parameters used to select the proper flow meter technology for a specific application. Other factors that help determine the right flowmeter are the product measured, its flow, the equipment’s price, maintenance cost, and accuracy.

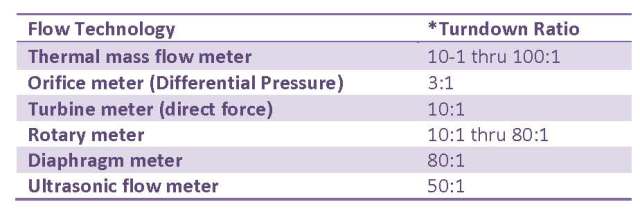

The chart below includes the turndown of various flow technologies.

The Sage Metering thermal gas mass meter has a wide turndown of 100:1 (with 1000:1 possible upon request), which is hugely desirable for natural gas applications because of the large swings in demand throughout a day as well as seasonal fluctuations.

Request Information on Sage Metering

The turn-down ratio is one of the first parameters to consider when ascertaining which flow technology to use for your natural gas application. For more information, read, “What is a thermal mass flow meter?”

* Please note that these figures are a guideline and referenced and will vary from manufacturer to manufacturer.

Dear Ms. Susan

we would like to reproduce flaring gas in our company .

first we want to instal in- line flow meter.

1- the flare line is 54″ . could you please direct me to select flow meter?

2- could we measure fluid flow without measuring it’s density?

Nice to see a info site like this one. I have been in the natural gas industry for over 30 years working in the St Louis metropolitan area.I would just like to bring up more information you may want to ad to your regulator ordering and installation instructions.#1 you mention nothing about regulator positions (A.B.C. or D). #2 There is nothing on the use of manometer or inches gauge that is used to check pressures (lock up & working).#3 Very little info. on piping used to vent regulators used on inside installations.Thanks for reading & feel free to contact me contact me. Bob

I appreciate the article, but I am still uncertain how if any calculations I would make in choosing a meter. In other words, I read what you saying, but now what? In other words, how do I apply this Rangeablity factor?

For me personally, if I have a 3M Roots Rotary meter, and the Rangeability is say 80 to 1, what now? They’re just numbers to this ol dummy.