GPL 750 Odorizer

The GPL 750 odorizer provides an eco-friendly approach to accurate, optimal, and consistent gas odorization for low-volume (even no-flow) and intermittent-flow applications of natural gas and propane. The GPL 750 RNG is ideal for biomethane (renewable natural gas), and biogas.

Eco-Friendly • SMART • Low and Intermittent Flow Odorization

The GPL 750 odorant injection system uses advanced proprietary technology to deliver precise odorization in even problematic conditions, such as low-volume (also no-flow) and intermittent-volume settings. The odorizer is suitable for municipalities, small city gate stations, and biomethane and biogas producers. The system’s PLC receives flow information and automatically counterbalances the injection rate to provide uniform odorant distribution.

Batch Odorant Injection for Pipelines:

1 to 225 PSI (1 – 15.5 Bar) Standard

No Flow to 24 MMSCFD*

(*injection rate of 0.5 lb./MMSCFH)

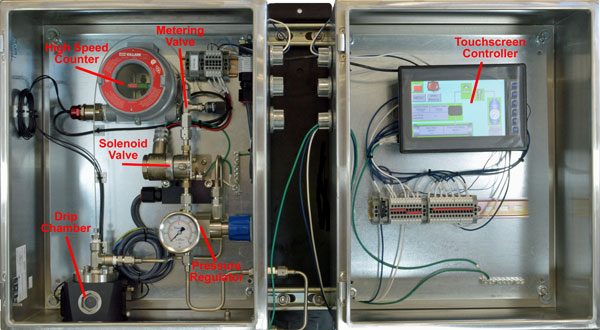

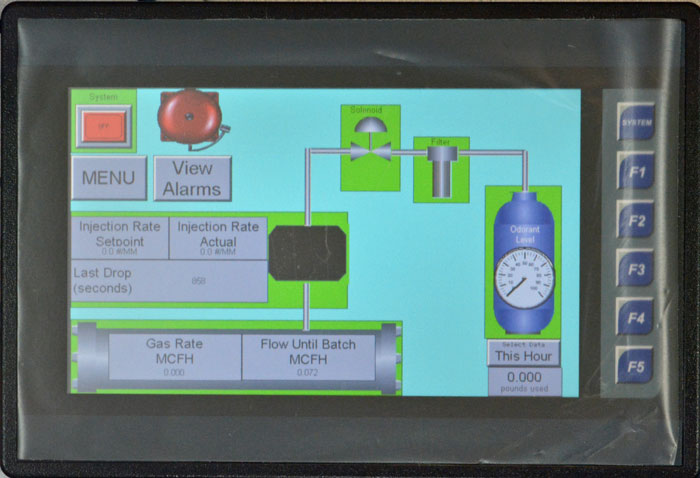

The GPL 750 odorizer utilizes patented drip technology to inject a fixed volume of mercaptan (odorant) into the gas stream. This precise injection ensures accurate and repeatable odorization at varying flow rates. It integrates Horner's most innovative controller to interface with the injector and all essential mechanisms to sustain continuous odorant injection relative to gas flow. The user can log into the controller remotely via computer, smartphone, or tablet to respond to alerts, change parameters, or program the unit. Of course, onsite programming is a breeze with its programmable touchscreen.

The GPL 750 odorizer utilizes patented drip technology to inject a fixed volume of mercaptan (odorant) into the gas stream. This precise injection ensures accurate and repeatable odorization at varying flow rates. It integrates Horner's most innovative controller to interface with the injector and all essential mechanisms to sustain continuous odorant injection relative to gas flow. The user can log into the controller remotely via computer, smartphone, or tablet to respond to alerts, change parameters, or program the unit. Of course, onsite programming is a breeze with its programmable touchscreen.

Features

Features

- No odor operation

- High rangeability

- One moving part

- Wireless modem

- Interfaces with SCADA Systems

- Remote communication using Modbus or wireless modem

- Real-time mobile alerts

- Online monitoring

- Industry-leading PLC

- Large, intuitive 7" color touchscreen

- SD card data storage

- No additional software is required.

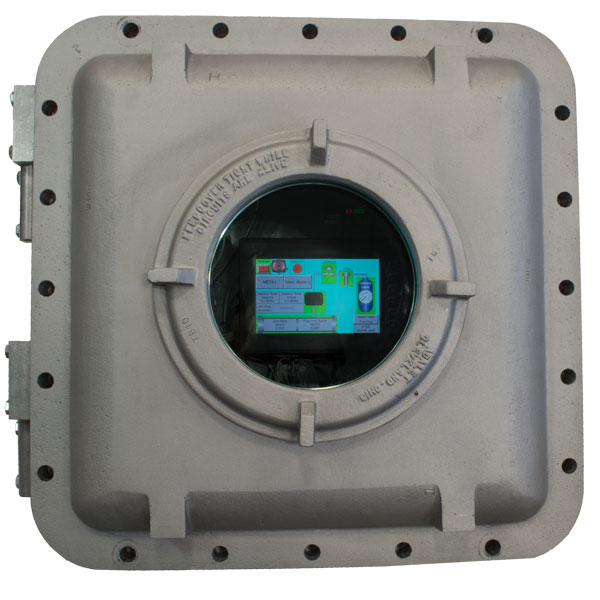

- Cl I Div 2, Groups C and D

Here is a mobile turnkey odorant injection system, featuring the GPL 750 Odorizer, odorant tank, containment, GPL 100 Flow Meter, and pipeline tap assembly (not visible), on a portable skid.

Benefits

Advanced Technology - Remote Monitoring and Mobile Alerts

- Real-time mobile alerts to smartphones and computers

- The data stores on PLC SD Card

- Automated remote monitoring using Modbus or wireless modem

- Audit trail reports for regulatory or company inspections

- No additional software required

Eco-Friendly - No Odorant or Gas Discharge

- No gas or odorant discharges to the atmosphere

- No smell during operation and maintenance

- Lowers false leak-call complaints

- Saves pipeline gas

Cost-Effective and Simple

- One moving part

- Minimal fittings and tubing for long-lasting performance

- No pneumatic pumps –minimum annual maintenance

Accurate and Reliable - Even in Problematic Flow Ranges

- Precision odorant injection relative to the gas flow

- Eliminates under- or over-odorization issues

- Exceeds 49 CFR § 192.625 (e) Odorization of gas

- GPL 750 product sheet

- GPL 750 RNG product sheet

- GPL General brochure

- Design Questionnaire

- GPL Odorant Injection Principle of Operation

- Mobile Odorization Unit

- GPL Odorization Training Classes

Specifications

- No flow–750 MCFH gas systems

- Up to 250 psi (17 bar)

- High turndown ratio (high rangeability)

- Class I Div. 2 (Class I Div. 1 optional)

Options

- GPL 100 Thermal Mass Flow Meter

- Service maintenance package

- Lease options available

- Cl I Div 1 hazardous classification

- Catalytic Heater

- Thermoelectric generator

- Solar panel

- Portability or mobility

Upgrades to Systems

- Turnkey odorization packages

- Tanks and Containment

- Fiberglass Buildings

- Temporary Odorization or Pickling Units